Liberty Industries CLEANROOMS

CUSTOM-DESIGNED HARDWALL CLEANROOMS

A cleanroom is sometimes called a clean room or white room, and those of a lower classification can be called a gray room. They are used in applications ranging from medical and pharmaceutical to scientific laboratories to many kinds of manufacturing processes. The primary reason for contamination control is to greatly minimize and control the pollutant level in the air.

Environmental contaminants are many–dust, airborne microbes, fumes from chemicals, aerosol particles, skin cells, hair, and others. Certainly one of the most contaminating factors is a PERSON! Regardless, the measurement method for a cleanroom is based on the International Organization for Standardization (ISO) specifications by controlled level, described from highest to lowest–Class 1, 10, 100, 1000, 10000, and 100,000.

The defining formula refers to a number of particles of a specific particle size per cubic meter. For example, in the neighborhood where you live, there would be approximately 35 million particles/m³ (cubic meter), with the diameter of the particles being .5µm and larger (e.g. ISO 9). Compare that to an ISO 1 clean room that must restrict particles of that particle size to ZERO, and have UP TO 12 particles/m³ of .3µm and smaller.

In designing any controlled environment to ISO and/or Federal Standard 209’s demanding specifications, Liberty’s engineering team has a number of exacting data it requires Midstates Marketing to obtain. Midstates Marketing can email, phone or fax the form that needs to be completed for them, and we will work closely with you to convey what you’re wanting to Liberty’s engineers. (A summary of the information needed is shown below). Their Model 7300 series pre-engineered and pre-fabricated cleanrooms are self-supporting and can be manufactured to any size you need.

CLEANROOM SPECIFICATIONS:

CLEANROOM SPECIFICATIONS:- In order to quote a custom cleanroom, a facility is going to need to accumulate information about a lot of key factors. These include:

- Information about the room itself–dimensions. cleanroom class, stand-alone/hung/attached, softwall/modular/hardwall, construction materials, gowning or ante-room, windows/doors, pass-thru’s or air shower, electrical outlets, cubit feet per minute of airflow in and out, lighting, flooring, air conditioning, etc.

- Information about the equipment that will be in the room and what heat-generating instruments will be inside.

- Information about the building facility or plant the cleanroom is in–how far is it to the nearest outside wall/A-C condenser/roof/ceiling/sprinklers/truck dock/duct work/power sources and what are the specs (e.g. voltage/phase/amperage, etc.).

- What assets or restrictions exist, such as a sketch/blueprints, union labor, etc. and what are the details as to how the room will be used (number of workers, shift schedule, traffic, etc.)

- All this is clearly specified on the 4-page form which we will email you!

CLEANROOM INSTALLATION

Liberty Industries typically has an experienced construction manager coordinate local sub-contractors in your area to build your cleanroom in your facility, e.g. a mechanical contractor, an electrical contractors, an HVAC specialist, etc., with Midstates Marketing assisting in being the liaison between you and Liberty. Their team’s engineering consulting, installation and service calls will be described and clarified in the quotation you receive, and, if needed, expediting of the project can be done for an added fee when overtime, working through weekends or holidays, etc. occurs.

CLEANROOM SERVICING

Liberty offers internal environmental control, certification testing and servicing on both cleanrooms and laminar flow equipment. (See other sections of this webpage and www.liberty-ind.com.) Quoting upon your request, the engineering and service departments offer:

*troubleshooting and service of your cleanroom frame and filtering system

*contamination testing services on laminar flow equipment

*rental and leasing of equipment

*seminars and in-house training programs

PRE-DESIGNED OPTIONS:

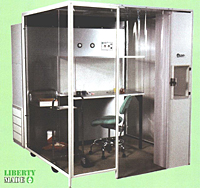

THE MOBILE IV PREP ROOM

Liberty offers a 6X8′ Model 1200A and an 8X10′ Model 1200B to help in meeting guidelines for compounding non-sterile preparations, e.g. for the home healthcare industry. Easy to move and disassemble, pre-engineered and fabricated, the Liberty Model 1200 can get your company up & running in no time, so contact us right away if this is something of interest!

THE IV 7300 MODULAR CLEANROOM

Liberty Industries, designed with sterile compounding in mind, is a modular clean room that can be manufactured with soft walls or a solid acrylic wall, and can be custom-designed to fit even the most difficult space restrictions. The IV 7300 is intended to meet or exceed USP<797>, can have an anteroom, as well as pre-engineered filtration, relative humidity, and temperature controls, if needed. It can be disassembled and moved, or made larger to adjust to your changing requirements.

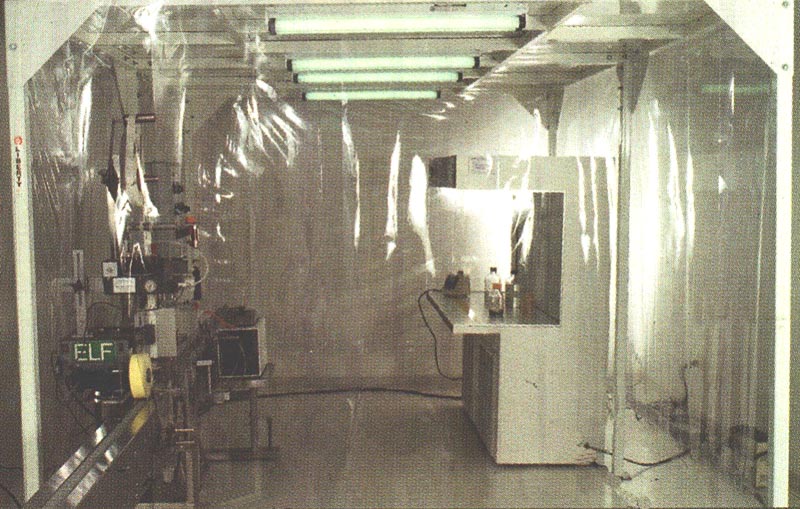

The VFCS Series–VERTICAL FLOW COMPONENT SYSTEM Softwall Cleanrooms

The VFCS modular cleanroom shown below is a mature product design that is continuously improved over the years. Liberty offers this vertical laminar flow system which is 115V/10/60Hz and constructed of a 7.5′ tall tubular steel frame. It uses Liberty’s MAX-8005 motorized 2X4′ fan-filter ceiling module and pre-filters, single-tube fluorescent lights, and vinyl curtain. Many options are available that aren’t listed here, including casters, flo-thru troffer lights, static bars, removable ceiling access panels, 277V/10/60Hz, special colors, an ante-room, etc., but we can discuss those when we communicate.

This curtain acts as an air containment device to assure Class 100 (ISO 5) air flowing down and over the critical work area. Lighting will supply 100-125 FTC over the work surface at a height of 30′ from the floor.

*Frame is primed and painted with polyurethane, standard with leg levelers.

*20 mil vinyl extending to 1 foot from the floor.

*Single-tube fluorescent lights with shields mounted directly to the frame; supply 100-125 foot candles 30 inches from the floor.

*One 4′ (w) X 6.5′ (h) 20 mil thick strip curtain door

*Lights and ceiling modules are wired on location and the unit is shipped disassembled with well-explained instructions included for quick and easy set-up by your maintenance crew.

*Available in Class 10/100/1000/10,000/100,000.

*Quoted upon request to your specifications.

|

| VFCS SOFTWALL | ||

| CLEANROOM | ||